Diesel Generator/Electric Drivetrain Hybrid systems

US UPfit

Technology

US UPFIT’s technology integrates advanced diesel-electric hybrid systems with proprietary software and hardware, ensuring seamless performance and efficiency. By combining industry-standard electronics with custom-designed components, US UPFIT delivers reliable, high-performance solutions tailored to meet the specific needs of modern fleets.

Why Diesel/Electric Hybrid?

Choosing a Diesel/Electric Hybrid over a fully Electric Vehicle (EV) offers several distinct advantages. Diesel engines provide a higher energy density compared to batteries, enabling greater range and power, particularly beneficial for heavy-duty and long-haul applications where refueling infrastructure for EVs might be limited. Hybrids also offer the flexibility of using the electric motor for short, low-speed trips and the diesel engine for longer distances, reducing range anxiety and downtime associated with charging. Additionally, hybrids can significantly reduce fuel consumption and emissions compared to traditional diesel vehicles, while still maintaining the robustness and reliability required for demanding operations. This combination ensures a more versatile and practical solution, especially for fleets transitioning to greener technologies without compromising on performance or operational efficiency.

What's the future of EV Hybrids?

Diesel/Electric Hybrids offer a flexible platform that can be adapted to future advancements in alternative fuel technologies. In the near future, hybrid systems can be swapped out with hydrogen fuel cells, which produce zero emissions and offer high energy efficiency. Other options include natural gas engines, which burn cleaner than diesel, and advanced battery technologies, such as solid-state batteries that promise greater energy density and faster charging times. This adaptability allows fleets to transition seamlessly to the most efficient and environmentally friendly technologies available, ensuring long-term sustainability and compliance with evolving regulations. By choosing US UPFIT’s hybrid systems, you are investing in a versatile solution that can evolve with the rapidly changing landscape of fuel technologies.

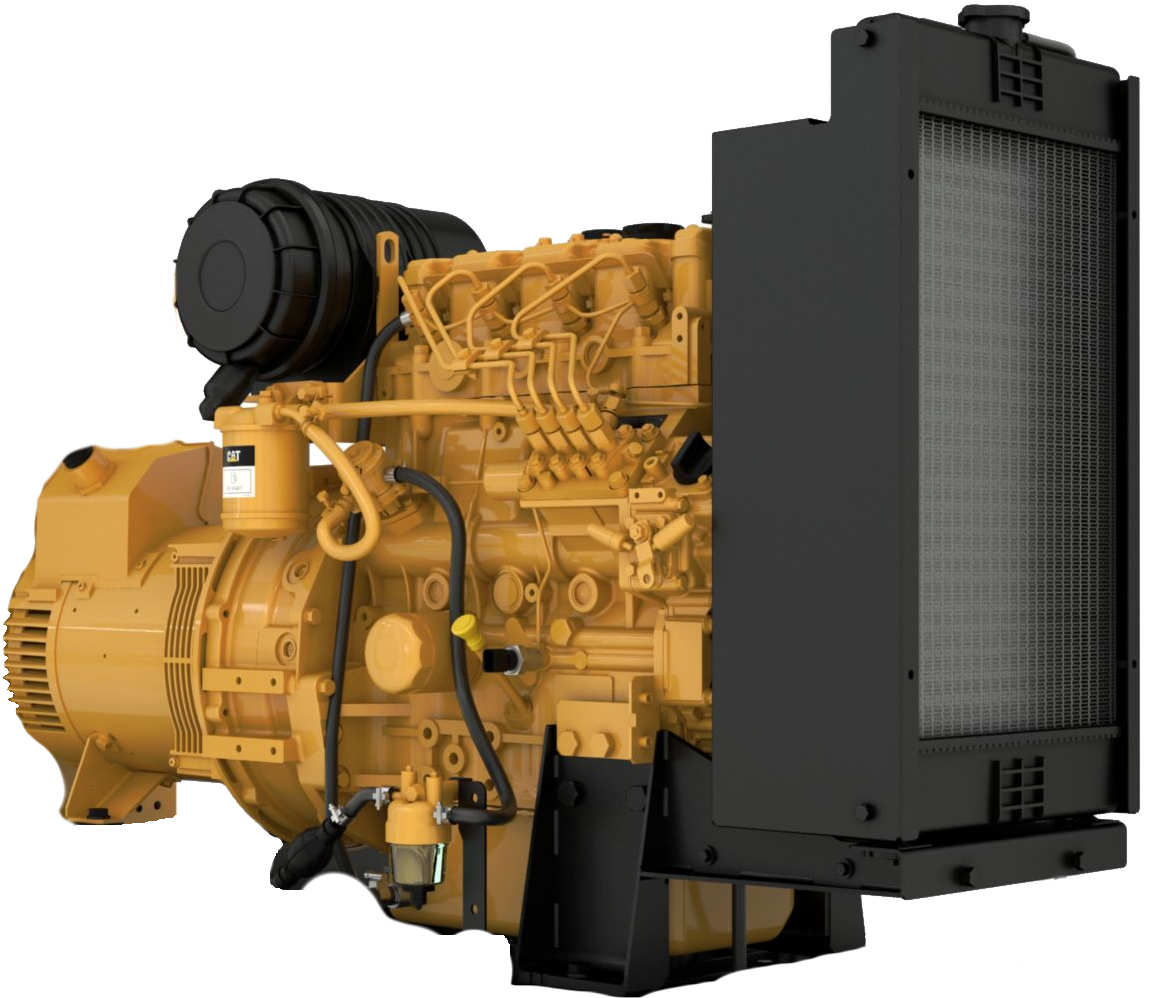

Diesel Engine

US UPFIT is proud to integrate Caterpillar 3.6 engines into our state-of-the-art Hybrid/Electric Drivetrain kits. Known for their reliability and efficiency, Caterpillar’s 3.6 engines provide a robust foundation for our hybrid systems, ensuring exceptional performance and durability. These engines are designed to deliver consistent power while reducing fuel consumption and emissions, making them an ideal choice for our eco-friendly conversions.

Details

| Engine Model | Cat® C2.2, In-line 4, 4-cycle diesel |

| Bore | 3.3 in |

| Stroke | 3.9 in |

| Displacement | 135.2 in³ |

| Compression Ratio | 22.5:1 |

| Aspiration | Naturally Aspirated |

| Fuel System | Indirect Injection |

| Governor Type | Mechanical |

Generator

Caterpillar generators are renowned for their exceptional reliability, efficiency, and robust performance. Integrating these generators into our hybrid systems ensures consistent and efficient power generation, significantly enhancing the overall performance and durability of your vehicles. Caterpillar’s cutting-edge technology complements US UPFIT’s innovative hybrid solutions, providing your fleet with reduced emissions, lower fuel consumption, and improved operational efficiency.

Details

| Maximum Rating | 20.0 ekW |

| Minimum Rating | 15.5 ekW |

| Emissions/Fuel Strategy | R96/EUIIIa Equivalent |

| Voltage | 110 to 415 Volts |

| Frequency | 60 Hz |

| Speed | 1800 rpm |

| Duty Cycle | Standby, Prime |

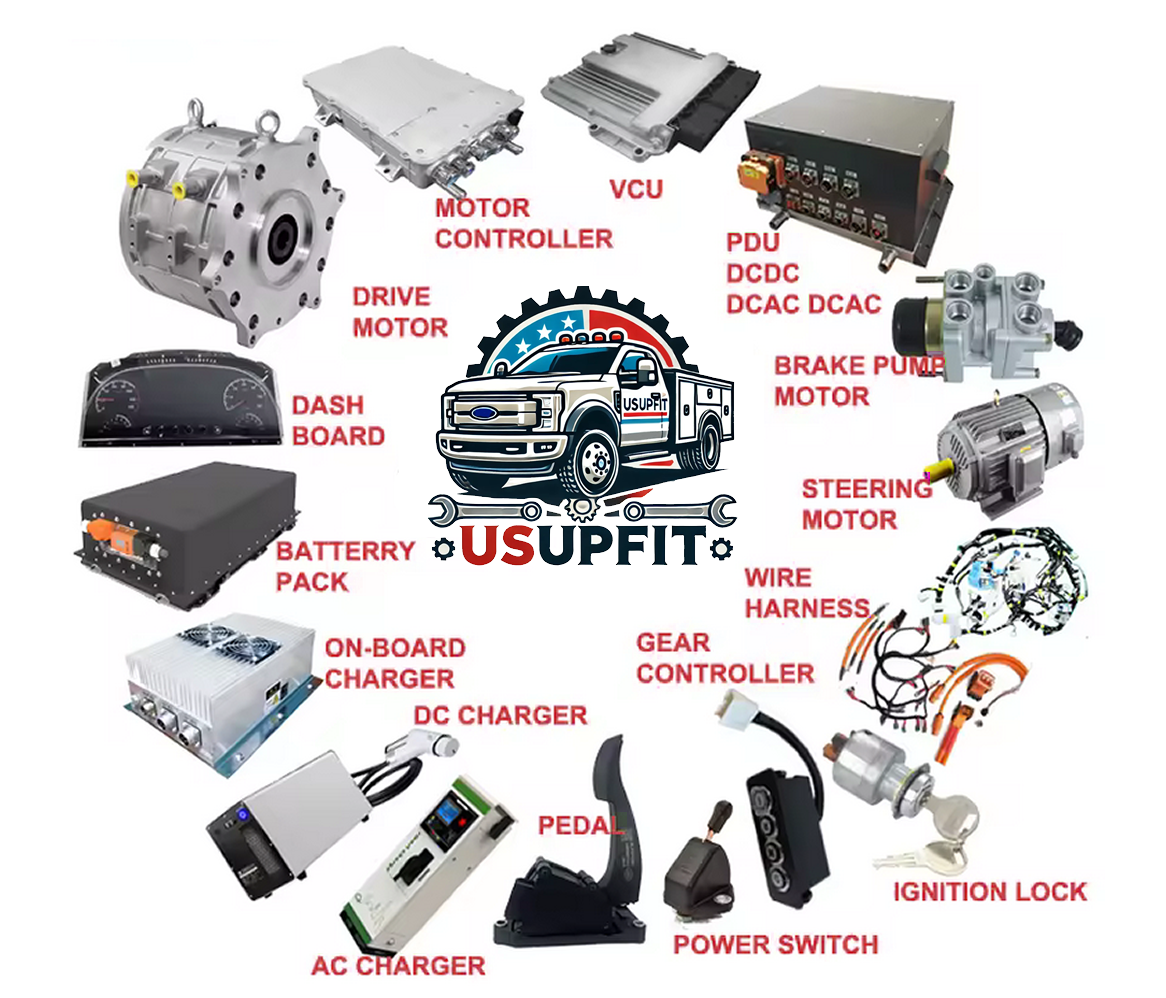

Electronics

US UPFIT’s Hybrid/Electric Drivetrain kits are a unique blend of industry-standard electronics and our proprietary software and hardware solutions. By combining reliable off-the-shelf components with custom-designed technology, we ensure our hybrid systems deliver unparalleled performance, efficiency, and reliability. Our proprietary software optimizes energy management and power delivery, while our custom hardware interfaces seamlessly with existing vehicle systems, enhancing functionality and ease of use.

Regenerative Braking

US UPFIT’s Hybrid/Electric Drivetrain kits are equipped with advanced regenerative braking technology, transforming the way your fleet operates. This innovative system captures kinetic energy during braking and converts it into electrical energy, which is stored in the battery pack for later use. By integrating regenerative braking, US UPFIT not only enhances fuel efficiency and extends the driving range but also reduces wear and tear on traditional brake components.

Batteries

Our kits feature state-of-the-art lithium-ion batteries, providing superior energy density, longevity, and efficiency. These high-capacity batteries are designed to store more energy, enabling longer driving ranges and enhanced performance. With a focus on durability, our lithium batteries ensure consistent power delivery and robust performance in demanding conditions. The integration of advanced Battery Management Systems (BMS) guarantees safety and optimal battery health, maximizing the lifespan of your hybrid system.

Details

Cooling

US UPFIT’s kits incorporate advanced cooling systems to ensure optimal performance and longevity of all critical components. Our cutting-edge thermal management technology effectively maintains safe operating temperatures for the battery pack, electric motor, and power electronics, preventing overheating and enhancing efficiency. By utilizing high-quality materials and innovative design, our cooling systems provide reliable and consistent temperature control, even under demanding conditions.

FREQUENTLY ASKED QUESTIONS:

How far can the truck travel under electric power?

At US UPFIT, we understand the critical balance between performance and sustainability for your fleet. With our cutting-edge Hybrid/Electric Drivetrain kits, your F350 trucks will be equipped with a robust 150 kWh lithium-ion battery system, ensuring exceptional range and efficiency.

On a full charge, your F350 can travel between 225 to 300 miles before the diesel generator needs to activate. This impressive range is achieved by leveraging the high energy density of our advanced lithium-ion batteries, coupled with an efficient electric drivetrain designed specifically for heavy-duty applications.

Key Benefits:

- Extended Range: Travel confidently knowing your F350 can cover substantial distances on electric power alone.

- Reduced Emissions: By primarily relying on electric power, your fleet will significantly lower its carbon footprint.

- Operational Cost Savings: Decrease fuel consumption and maintenance costs with our state-of-the-art hybrid technology.

Additionally, regardless of how far the battery will take you, your range is further extended, and any anxiety is alleviated by our diesel generator. This generator kicks in seamlessly when the battery is low, running at an even RPM to provide consistent power, ensuring that your journey continues smoothly without interruption.

Whether your trucks are navigating urban environments or tackling long-haul routes, US UPFIT’s hybrid solutions ensure optimal performance and sustainability. Join us in revolutionizing the future of transportation—where efficiency meets eco-conscious innovation.

Technology Stack

Diesel Engine:

Our high-efficiency diesel engine acts as a backup power source, only activating when the battery levels are low. It does not power the transmission directly, ensuring the entire drivetrain remains electric.

Electric Motor:

The robust traction motor drives the vehicle’s wheels using electric power, effortlessly handling the truck’s load and operational demands.

Battery Pack:

Our high-capacity lithium-ion battery pack stores electrical energy to power the electric motor, ensuring high energy density and longevity. The Battery Management System (BMS) monitors and manages the battery pack for safe and efficient operation.

Power Electronics:

- Inverter: Converts DC power from the battery pack into AC power to drive the electric motor.

- DC-DC Converter: Steps down high-voltage DC power from the battery to lower voltages for auxiliary systems and components.

- Charger: Recharges the battery pack from external power sources.

Transmission and Drivetrain Components:

- Electric Transmission: Exclusively uses electric power to drive the wheels.

- Drive Shaft: Transfers power from the electric transmission to the wheels.

- Differentials: Splits power between the truck’s wheels for smooth turning.

Control Systems:

- Vehicle Control Unit (VCU): Manages the interaction between the electric motor, diesel engine, and battery pack.

- Electric Control Unit (ECU): Specifically manages the electric motor and its interactions with the drivetrain.

Cooling Systems:

Our thermal management system ensures that both the battery pack and the electric motor operate within safe temperature ranges.

Auxiliary Systems:

- Electric Power Steering: Reduces parasitic load on the diesel engine.

- Electric Brake Booster: Enhances braking performance and integrates regenerative braking to recapture energy.

- HVAC System: Efficiently provides heating and cooling using electric power.

Mounting and Structural Components:

- Engine Mounts: Custom mounts secure the backup diesel engine and electric motor.

- Battery Enclosures: Protect the battery pack to ensure safety and structural integrity.

Wiring and Connectors:

- High-Voltage Cables: Connect the battery pack, inverter, motor, and other high-voltage components.

- Connectors and Relays: Ensure reliable and safe electrical connections.

Additional Elements:

- Regenerative Braking System: Captures and stores energy during braking to recharge the battery pack.

- Software and Calibration: Custom software manages the hybrid system’s operation and optimizes performance.

Caterpillar c2.2 Generator

150kwh battery

Off-the-shelf and propreitary hardware

Theorem

Ford F350 Weight As-Is

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Ford F350 Weight with Conversion

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Caterpillar C2.2 Generator Specifications

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

150kWh Battery Specifications

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Electronics Specifications

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Ford F350 Drivetrain Weight VS Diesel/Electric Hybrid Weight Compared

The drivetrain of a 2024 Ford F350, including the engine, transmission, transfer case (if applicable), and other related components, varies in weight depending on the specific configuration and options chosen. Here’s an estimate based on typical component weights:

Key Components of the Drivetrain:

-

Engine:

- 7.3L V8 Gasoline Engine: Approximately 540-600 lbs.

- 6.7L Power Stroke V8 Diesel Engine: Approximately 1,100-1,200 lbs.

-

Transmission:

- 10-speed Automatic Transmission: Approximately 300-400 lbs.

-

Transfer Case (for 4×4 models):

- Approximate Weight: 150-250 lbs.

-

Driveshafts and Axles:

- Front and Rear Driveshafts: Approximately 100-150 lbs.

- Front and Rear Axles: Approximately 500-700 lbs each, depending on the axle type (e.g., standard or heavy-duty).

Total Estimated Weight:

The total weight of the drivetrain components can vary significantly based on the engine choice and whether the vehicle is equipped with 4×4. Here are the approximate total weights for different configurations:

-

Gasoline Engine, 2WD:

-

Gasoline Engine, 4×4:

-

Diesel Engine, 2WD:

-

Diesel Engine, 4×4:

Considerations:

- Configuration: Weights can vary based on the specific configuration and optional equipment.

- Components: Additional components like cooling systems, exhaust systems, and mounts also contribute to the overall weight but are not included in this estimate.

- Sources: These estimates are based on typical component weights and manufacturer specifications.

Weight of the 2024 Ford F350 drivetrain:

The drivetrain of a 2024 Ford F350, including the engine, transmission, transfer case (if applicable), and other related components, varies in weight depending on the specific configuration and options chosen. Here’s an estimate based on typical component weights:

Key Components of the Drivetrain:

- Engine:

- 7.3L V8 Gasoline Engine: Approximately 540-600 lbs.

- 6.7L Power Stroke V8 Diesel Engine: Approximately 1,100-1,200 lbs.

- Transmission:

- 10-speed Automatic Transmission: Approximately 300-400 lbs.

- Transfer Case (for 4×4 models):

- Approximate Weight: 150-250 lbs.

- Driveshafts and Axles:

- Front and Rear Driveshafts: Approximately 100-150 lbs.

- Front and Rear Axles: Approximately 500-700 lbs each, depending on the axle type (e.g., standard or heavy-duty).

Total Estimated Weight:

The total weight of the drivetrain components can vary significantly based on the engine choice and whether the vehicle is equipped with 4×4. Here are the approximate total weights for different configurations:

- Gasoline Engine, 2WD:

- Gasoline Engine, 4×4:

- Diesel Engine, 2WD:

- Diesel Engine, 4×4:

Considerations:

- Configuration: Weights can vary based on the specific configuration and optional equipment.

- Components: Additional components like cooling systems, exhaust systems, and mounts also contribute to the overall weight but are not included in this estimate.

- Sources: These estimates are based on typical component weights and manufacturer specifications.

The Caterpillar C2.2 generator is a compact, efficient diesel generator designed for various applications. Here are the specifications regarding its power output:

Caterpillar C2.2 Generator Specifications:

- Power Output:

- The C2.2 can generate between 27 kW to 60 kW of electrical power depending on the specific model and configuration.

- Common Rating: One of the common configurations of the C2.2 is rated at 50 kW for continuous power.

Details:

- Fuel Type: Diesel

- Cooling System: Liquid-cooled

- Operational Range: Designed to meet various international standards and can be used in different environments, from construction sites to backup power for commercial buildings.

References:

- Caterpillar Official Website – Provides detailed specifications and various configurations available for the C2.2 generator.

- Product Brochures and Technical Data Sheets – For detailed information and performance metrics.

How far can a 2024 F350 travel with a 150kWh battery and a Caterpillar C2.2 generator outputting 50kw?

1. Initial Range from Battery:

Assuming the vehicle’s energy consumption rate is 2 miles per kWh:

- Battery Capacity: 150 kWh

- Range from Battery:

2. Additional Range from Generator:

The 50 kW generator can extend the range by recharging the battery or directly powering the electric motor. Assuming continuous operation:

- If the generator runs for 1 hour, it produces 50 kWh, which adds 100 miles to the range (as calculated previously).

To understand the generator’s contribution over time, we need to determine how long the generator will run and the vehicle’s travel time.

3. Combined Range Calculation:

Let’s assume the vehicle is driving and the generator is running continuously to provide additional power.

- Travel Speed: Assume an average speed of 60 miles per hour (mph).

- Generator Running Time: The generator will be running while the vehicle is moving.

Example Scenario:

- Initial Range from Battery: 300 miles

- Generator Contribution: Calculate how much the generator adds for continuous driving.

For each hour of driving:

- Distance covered: 60 miles (at 60 mph)

- Energy required: 60 miles / 2 miles per kWh = 30 kWh

- Energy produced by generator in 1 hour: 50 kWh

- Net energy added to the battery in 1 hour: 50 kWh – 30 kWh = 20 kWh

Total Range Calculation:

- The generator effectively adds 20 kWh of energy per hour of driving, which translates to:

Therefore, for every hour of driving, the generator adds 40 miles to the range beyond the initial 300 miles from the battery.

Continuous Driving Scenario:

If you start with a full 150 kWh battery:

- Initial Range: 300 miles (from the battery)

- Additional Range per Hour: 40 miles (from the generator)

- Total travel time to deplete the initial battery: 300 miles / 60 mph = 5 hours

After 5 hours, the generator will have added:

5 hours×40 miles/hour=200 miles

Total Estimated Range:

- Initial Range: 300 miles

- Additional Range from Generator: 200 miles

Total Range=300 miles+200 miles=500 miles

Conclusion:

With a full 150 kWh battery and a continuously running 50 kW generator, the Ford F350 could travel approximately 500 miles. This assumes an average speed of 60 mph and an energy consumption rate of 2 miles per kWh.

Get In Touch

Location

Seattle, WA

sales@usupfit.com

Hours

Mon – Fri

8AM – 2:30PM